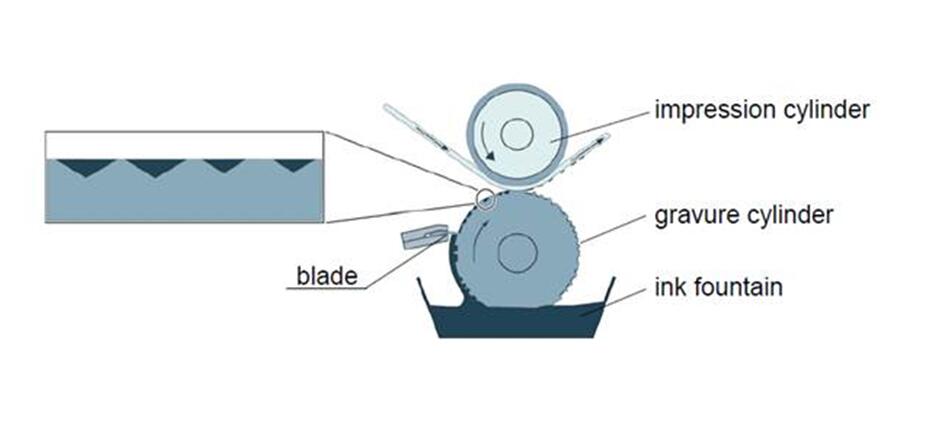

The doctor blade is mounted in a way that it uniformly meters the ink from the anilox prior to distribution onto the printing plate, as shown in the illustration.

Key factors of success include:

- Angle of blade to anilox roll per press specs

- Correct pressure of blade needed to roll (the least amount needed)

- Perfect alignment with the anilox axis of rotation

- Correct blade design, size and material for both press and job

- Easy and fast replacement as the blades wear out

- Using the designated size specified for each press

Failure to adhere to these six factors will result in varied ink distribution and may reduce the life of the anilox roll.

As the doctor blade scrapes (or meters) away the excess ink from the anilox roll, it then coats a precise film of ink onto a printing plate. The amount of ink reaching the plate

determines the accuracyof the printed image on the film, paper or corrugated substrates. See illustration above.

It is important to note the following:

- Anilox rolls often cost thousands of dollars; however, if they are cared for and maintained correctly, an anilox can last years in many print applications unless inadvertently damaged in handling or cleaning.

- Doctor Blades cost very little and are designed to wear out smoothly in an attempt to maintain consistent ink metering for distribution throughout the print cycle. Changing and checking blades often can avoid print issues & damage to the anilox roll.